www.ConcreteCottage.com

www.ConcreteCottage.com

Chronicles of the Design & Construction of Two Waterfront Hurricane Proof Dry Stack Modular Green Custom Homes

1. Villa Lagoon, Wilder Italian Style Home

2. Nasello Italian Style Home

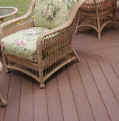

Wood Composite Decking, Man Made Rails, Docks and Fencing, Man-Made Materials

While researching composite decking materials I have compiled a good list of suppliers of this new building material. According to the Mother Earth News, (yes it is still around, after all these years :o) ...

Composites or man made decking materials are a great choice for any surface where you or your children are likely to make skin contact, particularly decking, rails and outdoor tables. These products also are much easier to clean than wood, and you don't have to worry about getting splinters in your hands or feet. Many of the plastic milk bottles, detergent containers and grocery bags we recycle are being mixed with wood fiber to make a new generation of decking material called composite lumber. This recycled plastic lumber is now available in many home-improvement stores as well as lumber and building supply sources.

These products last as long as arsenic-treated wood. Unfortunately they cost more. Manufacturers, however, say the increased cost is offset because the composite lumber doesn't need the periodic staining and sealing that traditional wood requires. Composite lumber can be twice as heavy as many softwoods, so it is not strong enough to use for structural members, such as load-bearing walls, deck frames or floor joists, but fine for the deck's surface.

You also can use recycled-plastic lumber in the garden, since it contains no arsenic or chromium to contaminate the soil.

Some suppliers of Man-made Composite Decking include:

Trex Composite Decking - Manufactures decking material made primarily from recycled plastic grocery bags, shrink-wrap, and waste wood. Trex Company created the category of composite decking materials. In fact, over one million homeowners across the country own a Trex deck. Trex has the longest record of proven performance. Trex offers a 25-year limited residential warranty on all products. Trex Company is the nation's largest manufacturer of composite decking, railing and fencing, with over 15 years of product experience. Best deck design ideas online. They have a Create Your Space Deck Designer, Your personalized deck report will provide:

- Material and color selections of the deck you designed

- Deck layout diagrams

- Listing of Dealers where you can purchase Trex products

- Listing of TrexPro contractors that can help you build your deck

- Parts of a deck diagram and glossary of terms

CertainTeed Corporation of Valley Forge, PA makes CertainTeed’s patented EcoTech™ material, which is a blend of PVC and recycled natural fibers. They are now offering Boardwalk® composite decking with deeper, richer colors that look like stained or painted wood and a new natural wood texture. The new line, Boardwalk® Signature HFS™ (Hidden Fastener System) is available in Chestnut, Cedar and Redwood. CertainTeed’s patented EcoTechmaterial combines PVC, a weatherable polymer, with 100% recycled maple wood flour The specially formulated surface provides scratch, stain and fade resistance. With Boardwalk’s EcoTech™ material, the planks are more dense and therefore less prone to stains vs. less dense/more porous PE-based composite planks. The ASA/PVC cap found on Boardwalk Signature HFS has no wood content to stain, providing a second layer of stain protection. The HFS Clips are applied to the top of the joists so there is no working under the deck and only one clip and screw is needed per joist. Look under 'Case Studies' to see some photos of the Boardwalk deck product on their site. Not too many exciting deck design ideas on this site. www.certainteed.com

AERT, (Advanced Environmental Recycling Technologies Inc.) A leader in wood composite technology. AERT began manufacturing decking systems in 1992 which were marketed under the trade names LifeCycle™. In that same year, AERT provided the decking material for the South Padre Island Convention Center Board Walk, which was the Company’s first high visibility public walkway. In 1995, AERT chose Weyerhaeuser as its national distribution and marketing partner for decking and accessories. AERT now makes two lines sold under two different names, Choice Dek and Mositure Shield. MoistureShield Professional Grade composite decking line features five new colors of decking, including two “exotic” colors designed to look like tropical hardwoods, a new matching handrail system with a more real wood look. www.aertinc.com

ChoiceDek - This product sold by Lowes, seems to have some bad reviews online. Some ChoiceDek customers have alleged that mold, mildew and other “black spots” have developed on their ChoiceDek decking boards and railings. Homeowners have alleged the mold spots are either difficult to keep away (requiring constant cleaning) or unsolvable (returning within a day or two).

ChoiceDek is a registered trademark of the Weyerhaeuser Company. There may be a class action lawsuit, not sure, but the website has a 'Submit warranty info here" link The problems everyone complains about is black spots and more black spots !! where the sun hits the composite decking. I do not see black spots in any of the lovely photos in their gallery ! www.choicedek.com

MoistureShield® - watchout: thunder and lightening on this website !! Moisture Shield Composite decking is manufactured in two textures and five colors that can be mixed to create stunning and unique deck patterns. They say that a comparison of composite decking vs wood shows that the best composite decking can last 50 years or longer! They have a informative cost comparison chart on the site. MoistureShield® 100% composite decking costs more initially compared to wood, but they say that you will save more than you pay in just a few years. When you consider the time and expense of maintaining a conventional wooden deck and the fact that MoistureShield® will last at least twice as long as a wooden deck, it makes sense to invest a little more and get a lot more. MoistureShield® and DIY Technologies have joined together to offer a tool for designing a custom deck for your home. It allows you to select your deck shape and size, add stairs and railings and additional levels. After you submit your custom design, a downloadable Deck Specification Kit gives you a 3D model of your design, a how-to checklist, tips for success, and a materials and cut list. www.moistureshield.com

TimberTech website has an online deck design system. You can use the interactive deck designer to make deck plans, and a 3-D rendering of your deck design. Choose the size, shape and color of your deck, add levels, stairs and railings, and create, change and save as many deck plans as you'd like. When complete, you can print out See some dream deck designs on the TimberTech site. TimberTech’s Earthwood Plank with VertiGrain™ surface has color and grain variations that emulate natural variations in real tropical hardwood. Time and exposure will enhance the natural color of the deck. Available in three warm, rich colors and two profiles. Available in Tropical Rosewood, Tropical Teak and Tropical Walnut. All colors are available in a grooved or solid plank. From what I have read, this brand may be one of the more expensive lines of composite decking, but it seems one gets what one pays for in this category. You can download specific information regarding the TimberTech 25-Year limited warranty additionally, TimberTech offers DrySpace a deck drainage system that collects the water that falls between the gaps in the planks and channels it away, leaving a dry and functional space below. Nice pictures but this would probably blow away in a storm down here. www.timbertech.com

Wishbone Industries - PermaDeck - They use 100% recycled plastic and metal to produce unique and stylish benches, picnic tables, trash receptacles, bike racks and more. Perma-Deck boards are an attractive, practical and innovative solution for long-lasting decks, porches and balconies. Perma-Deck is offered in 4 attractive colors: light grey, sandstone brown, beige and redwood to accommodate your individual decking needs. Perma-Deck is environmentally-friendly, ultra-durable and is made from 100% recycled plastic. Similar to wood, Perma-Deck can be drilled, mitered and sanded! Known for its high performance results. PermaDeck planks come in several styles, like tongue and groove, are designed to be used with screws or hangers like regular wood boards, no special clips or anything. www.cascadesreplast.com Wishbone also makes a landscape timber: XPotential Products are a plastic composite product manufactured with 100% recycled materials including post-consumer plastics and the non-metallic by-product from recycling automobiles. XPotential Products Inc. manufactures a plastic composite which is extremely durable, environmentally friendly and has a life expectancy of 75-100 years. Utilizing world-first technology, two plants have the production capacity to consistently supply landscape and garden supply centers, home building centers, lumber yards, environmental niche markets, wholesale distributors and discount chains. Looks interesting... www.xpotentialproducts.com

CorrectDeck - Manufactures composite decking lumber made from polypropylene and Maine hardwoods. Based in Biddeford, Maine, Correct Building Products is the manufacturer of CorrectDeck, a composite decking material made from 60% recycled hardwood sawdust and 40% polypropylene. Correct Building Products was founded in 1999 by two extrusion industry veterans with the goal of manufacturing technically superior, durable and sustainable composite building products for outdoor living. CorrectDeck products, including CorrectDeck, CorrectDeck CX, Dimensional Composite Lumber (DCL) and RapidRail are made from a patented wood fiber-polypropylene formulation. Lots and lots of deck photos, they let homeowners submit interesting photos that use their composite decking system. Looks like they make a dark green color that looks like painted porch flooring. www.correctdeck.com

GeoDeck Composite Decking and Railing system - ...The GeoDeck composite decking and railing system is available in three fade-resistant colors; Cedar, Driftwood, and Mahogany. They make tongue & groove and traditional deck boards and offer a 20-Year limited warranty. GeoDeck is the only brand on the market that contains Biodac®, an exclusive product made from purified cellulose fibers and other minerals. Unlike wood flour or wood chips used in other composite products, Biodac does not contain high amounts of Lignins—a major contributor to fading of composite material. GeoDeck replaces Lignins with Biodac and the result is a superior deck that looks great year after year. www.geodeck.com

WeatherBest® - made by L-P. Louisiana-Pacific Corp. - six colors and a complete line of railing.LP WeatherBest decking, which is made of wood and plastics, allows you to use all your regular tools.Made from a high-quality mix of plastics and wood, LP® WeatherBest® decking resists termites, rot, decay, and warping, and it will never splinter. LP WeatherBest is made of pre-consumer recycled wood particles and high density plastic. The added SmartGuard™ process fights off decay and winter mold. They offer a 10-year transferable limited warranty. www.weatherbest.com

Fiberon Decking - New Fiberon® Horizon™ and Fiberon Sensibuilt™ PVC decking deliver fade resistance with the industry's first 10 Year Fade Resistant Warranty. Patent Pending surface technologies offer unsurpassed stain, fade, scratch and mold resistance. Available in Jatoba, Mahogany and Cypress, the color and surfaces of Tropics decking mimic the look of tropical hardwoods. Fiberon offers six levels of composite decking and various products. The home page is slow loading for me, but there are good photos on internal pages. Looks like pretty snazzy stuff ! www.fiberondecking.com

N.E.W. Plastics Corp.- ReNew Decking - manufactures containers, plastic lumber, and components made from other prime and recycled material. The company's annual sales are $35 million and growing. EVOLVE plastic lumber, you get the beautiful, natural look of real wood decking, without all the worry and maintenance. EVOLVE plastic decking can be used to create any outdoor living space, from decks and docks to pergolas and playgrounds. Whatever you create, you’ll get attractive, timeless durability with the lowest long-term cost of ownership. The materials and projects shown on the website look pretty basic to me. www.renewplastics.com

It used to be that wood was the only decking material in use – this is not true anymore. With man-made decking material, you can be more creative than ever before. Man-made decking material offers many advantages over wood, so make sure you consider synthetic decking materials for your deck project. Here are some additional thoughts on the subject.

Keep in mind that by using man-made decking material you are helping reduce reduce the amount of deforestation on our planet. Many man-made wood look materials are made in factories without the use of any actual wood. Some products combine wood waste products with synthetic materials. If you are concerned about the environment, consider using man-made deck products.

TriMax Building Products - Maybe best for stalls and fences. Trimax Structural Lumber and/or Durawood Lumber offers the farm and equine industry two great options for durable and sustainable designs for horse stalls, fencing, and other applications. Durawood is great because it is resilient to urine, abuse, rotting, warping and mildew. Trimax Structural Lumber is a great fit for other applications such as fencing, bedding frames, decking and other applications. There has been a decline of cribbing of the horses after the Durawood has been installed. Unlike wood, the horses do not get any satisfaction from clamping down on the plastic lumber. Horse owners have been very happy and surprised with the results from using Durawood Lumber for their equine applications. Trimax Environmental Decking offers a hidden clip system, resistant to fading, stain resistant, mold resistant, wood grain embossing. By utilizing a combination of both Structural and Non-Structural Lumber, complete boardwalks, from the ground up can be built with Plastic Lumber. You can use Trimax for Posts, Girders, Joists, Blocking, Railing, Decking and posts. Trimax Environmental Decking and other accessories can be used for the decking, railing and other accessories. A hidden fastening system and a 5/4" face screwed board are both available as decking options. www.trimaxbp.com

Sensibuilt - a Fiberon company. Cellular PVC high end decking board this one comes is 4 very vibrant glossy colors and a fusion bonded surface said to resist chalking and scratching. Comes with a limited guarantee against color fading. In 2007 Bloomfield, Conn.-based Sensibuilt Building Solutions LLC got the financial backing of Pegasus Capital Advisors LP of Cos Cob, Conn., and has five principals - all of whom are veterans of the building products industry. In general, Sensibuilt Decking requires the same skills and tools you'd need to install a wood deck, but there are important differences. www.sensibuilt.com

Veranda Decking - Veranda (Universal Forest Products, Inc,) is the composite decking sold exclusively at Home Depot manufactured by the Fiberon company. Veranda has a new wood grain finish and is cheaper then the average composite. Veranda carries only a 15 year warranty. Veranda is said to be available in four colors (Cedar, Redwood, Gray and Tuscan Walnut) but only stocked in one color many times. If on a strict budget then this might be your choice. It is made of wood and plastic that is extruded with a reversible finish: combed finish on one side and an embossed woodgrain finish on the other. www.verandadeck.com.

More on Man-made Decking Material

Consumer Reports said that composite deck materials, which blend ground-up wood and plastic, are chipping away fastest at wood's popularity. Some, including Trex, contain recycled plastic. Composites eliminate the refinishing that wood requires every one to three years. Deeper graining and grooves help today's materials look more like wood; optional matching railings offer a unified look.

Their one-year exposure tests under teeming rain and scorching sun also include solid-plastic, aluminum, and some pricier wood alternatives to the usual pine. Consumer Reports didn't stain the test wood decking, as most people do, so the focus of the tests was on the wood itself. Staining would have helped wood keep its looks longer, but different stains would yield different results.

Consumer Reports showed that some synthetic decking didn't make the grade for rigidity.

Synthetics resist sun and spills. All of the composite, plastic, and aluminum decking kept its original color better than the unfinished wood. Many also had stain resistance against mustard, wine, and other spills.

Some decking is stiffer and surer. All of the wood and the LockDry aluminum resisted slips best in their wet and dry friction tests. Wood and aluminum were excellent at resisting bending and sagging. Some plastics and composites came close in those tests, but several flexed or sagged notably. The Trimax DuraWood plastic felt bouncy even at the usual 16-inch span, and the plastic Deck Lok scored lowest for sagging.

Synthetics offer a range of design options. Many of the synthetic products are available in a number of colors: white, gray, and several shades of brown. Surface textures include smooth (like plastic lawn furniture, in some cases), subtle wood grain, ridges, and other decidedly unwoodlike patterns. Some composite planks are flexible enough to be easily curved into patterns or shapes that would require much money and skill to duplicate in solid wood. This is am application where bendy man made wood could be used to great advantage.

More on Composite Decking Products

Back in 1992 when most decks were made from pressure treated lumber Mobil Oil bought the technology to make Trex ( called Rivenite at the time). Mobile Oil coined the term “composite decking” and spent plenty on advertising and information about Trex Decking which began the composite decking era. Now, 17 years later, there are dozens of composite decking companies and many choices. Even Trex now makes six different types of deck products. There are as many opinions on what makes a composite the best choice. Many times the choice is based on which is the most readily available product. Some materials have already come and gone, or changed to suit the trends. This can make working on a multi-stage project very difficult when you try to match the materials on the previous stage. Better to buy all you will need at one time.

Composites and manmade decking materials can be broken down into the following categories:

(note: more info available here http://www.deckspecialists.com/composite_deckmaterials.htm and our composite page http://www.deckspecialists.com/composites.htm )

Basic composites: single color simple grain or combed finish, mixture of recycled wood fibers, dust or flour and a plastic binder usually HDPE(high density polyethylene) mostly in the range of 50% plastic 50% wood. These are the cheapest man made boards and perform ok. Most will look similar, and have basic limited color choices. This man made deck material will require some periodic cleaning, and some care should be taken not to scratch or stain the decking.

Enhanced composites: Multiple color hues to more accurately simulate a natural wood species.

High end composites: a composite with superior grain and higher quality materials, finer wood dust or flour, usually less wood and more plastic, a better extruding process, better mix of polymers, still mostly HDPE but also polypropylene can be used for more strength. These materials are often coextruded with harder surfacing treatment or materials. They offer anti-microbial, scratch resistance, and/or UV protection. You will find these products to have a lot of variety in color, texture or surface graining and many are the the most natural looking of the man-made materials. Some look very similar to desirable real wood species. Some cleaning and preventive care is usually necessary. Pricing in this group ranges from affordable to quite expensive depending on the product. There are some very good buys in this group as well as some that are very expensive.

Cellular PVC was originally developed by Procell, but is now owned by Azek. It is a process where PVC (poly vinyl chloride) and sometimes a filler (processed flax seed or rice husks) is whipped into an aerated foam about ½ as dense as solid PVC. The results are a extruded material with a shiny hard surface and the working characteristics of wood. This is very different from hollow PVC materials. Cellular decking materials are gaining popularity and now even many of the composite manufactures also produce a cellular board. Cellular’s tend to be lighter and easier to handle, strong and less likely to scratch or stain. It is easy to fastening cellular material, no need to predrill or use special screws, wood screws are fine. But most are susceptible to chalking and definitely look less natural or more man-made than real wood. Another trend in high end man made composite lumber and some cellular PVC decking boards are the ones with co-extrusions or a bonded outer layers . What you get is an outer layer with special characteristics like more colorful, enhanced grain, harder and scratch resistant, maybe some anti-microbial qualities or mildew resistance, and often UV resistance.

Pricing: composites and cellular’s range greatly in cost. The basic composites, which are more than adequate for most projects are going to be your best buy, but still rely on petroleum and are influences by the price of oil. Expect to pay roughly 3 times more than wood. Many people still frame the deck from treated wood. The higher end composites and cellular PVC boards can get rather expensive. These high end features come with a high price tag but the higher end composites do perform better than the low end product.

Making a decision can sometimes come down to, what composite company’s colors best match the house or surrounding materials. Some composites attempt to look natural or emulate a natural wood species while others do not even try to look like wood. As many of the newer products are not time tested we will see if they live up to their promises and we will see who will stand the test of time. The economy has already resulted in some companies disappearing and other companies scrambling to merge and consolidate for profitability. All of the today’s products are way ahead of the first generation of Trex boards.

With all the different colors and types of composites and many of them being special order, it can be frustrating when ordering materials for a project. You want to have enough materials to finish the project and you don’t want to cut it too close come up short. Sometimes you cannot return the extras at all or sometimes there is just a restocking fee. Some builders and suppliers will just stick to one or maybe two composite brands and limit the amount of colors they offer to allow for returns and re-stocking of like materials.

How to save with Man Made Deck Materials

Man-made decking material can also be custom fit to any type of project. You can order the exact pieces you will need and have very little or no waste.

Some man made decking material requires more support underneath than long boards of wood do so you will need plans that are specific to composite decking material.

Man-made decking material doesn't require as much maintenance as wood decks do. You will not need to stain it and and you don't have to add a waterproof sealant to the surface in order to protect your deck. Generally you just wipe down the surface of your deck to keep it looking brand new. You may want to power wash it every so often if you have food spills and children's play-dough , etc.. .on it. There is a time and money savings since you won't need to re-treat the surface each year.

One thing to consider if using wood and man made 'wood' material together: I have read a bit of concern that the difference in material density between wood and the composite may be a factor. While the deck boards are supposed to resist swelling and moving in response to moisture - if that same decking is supported by pressure treated lumber--and the wood is still going to move some. There is some concern over the different rates of movement between the wood and decking. and I wonder if it might stress the fastener locations where the dissimilar materials meet.

Available in a wide range of materials including recycled plastic and wood fiber, plastic, vinyl, cellular PVC or aluminum, composites share one common characteristic: they’re easy to keep clean with an occasional squirt from a nozzle on a garden hose. That’s a real boon to homeowners who don’t have the time or inclination to keep a wood deck in top shape.

Though wood is still used in more than 75 percent of deck construction, composite decks are becoming more popular, despite their higher cost and exacting construction requirements.

Man-made decks are a growing part of the market for people with small children, little time and beach locations. More and more docks piers are using man made deck materials. They’re also finding a market among owners of seaside vacation homes and empty nesters.

According to John Mortimer, president of the North American Deck and Railing Association and owner of Sweetwater Decks in Tennessee, beachfront homes benefit the most for man made decking over wood decking. “The sun’s ultraviolet rays are killers for real wood and the beach is where they are most intense.” A constant source of moisture, especially salty moisture, can add up to more maintenance too. When you own a vacation property, you come there to relax, so the less maintenance the better!

Older people often prefer a low-maintenance deck to fit in with a lifestyle that no longer includes children living at home. Emphasis is on a bigger deck, shade, an outdoor kitchen, some subtle outdoor lighting, and maybe a fire pit. A real entertainment area for entertaining is often the goal.

Another prominent deck builder, Texas-based James McDowell of Accent Deck Works, finds consumer demand on the rise in a market that in recent years has been flooded with dozens of new composite products and manufacturers. But, he cautions, not all products live up to their marketing claims or warranties, making it more difficult for homeowners to select the right product.

Bet you didn't know that there is a Deck Expo ! Check it out.

Many Many brands sold online by Deck Specialists

See photos of decks uploaded by homeowners and contractors.

Marinas, piers and boardwalks

Man-made composite lumber is a perfect fit for your dock or marina. Most products can be used for pilings, joists, girders, decking and railing. You will worry less about maintenance issues with man made composite lumber. Only worry about hurricanes !

Many issues today in a vast majority of the country have risen regarding any type of pressure treated lumber being in contact with water, due to the leaching of the wood preservative in the water. By utilizing plastic and composite man made lumber for pilings, structural components and decking and railing, issues regarding environmental leaching may disappear.